Wide selection of files for all the needs of the designer. Installation Manual Operating Instructions.

All Putzmeister Catalogs And Technical Brochures

Research evidenceas to what affects concrete pumpability and how pumping changes concrete properties.

. Folding type folding type FFH CONTROL BLOCK GEAR PUMP folding type folding type ACCUMULATOR PUMP folding type Available for. The Manual for practitioners in Nigeria using concrete must now replace the foreign manuals which has. 3008 632 530 828 406 490 492 450.

SANY trailer mounted concrete pumps have contributed to every construction height breakthrough in China. Pumping processes and or into contractual requirements with third party contractors where pumping is out-sourced. To view the largest previews click on the icon at the top.

For given proportions of cement and aggregates without admixtures the higher the slump the wetter the mix. Concrete Pedestal Size 3 5 times pump motor mass Set 6 away from pump baseplate edge all sides Bush hammer floor slab Install Reinforcing steel into floor slab Apply bonding agent Pump anchors system. Consistency is the ability of freshly mixed concrete to flow.

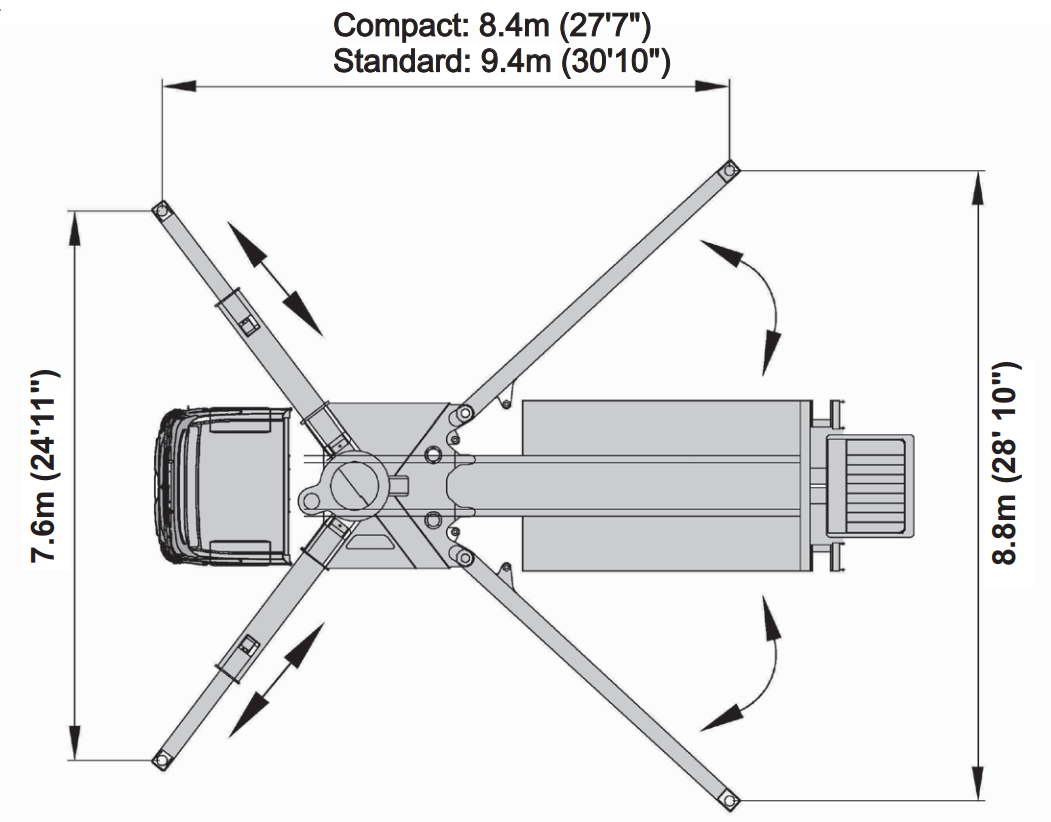

Sanford FL 32771. Boom concrete pumps allow the pipeline to reach along upwards and below. Hence tight spots can be cast by these pumps.

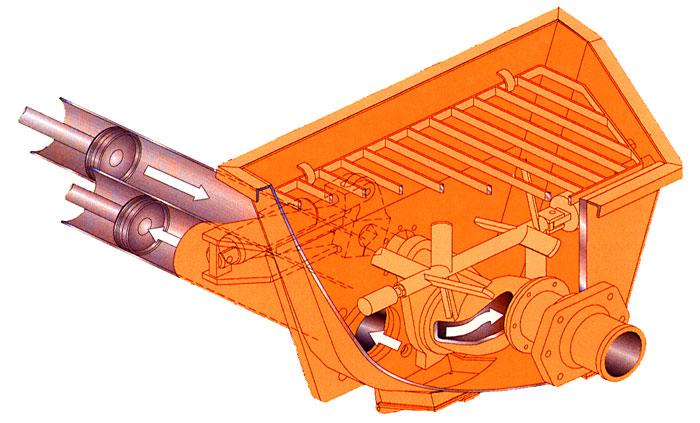

In this way the end-activator ie. The pumps shall be capable of maintaining their watertight integrity submerged under 80 feet of water. Powerful stationary concrete pumps are available as trailer concrete pumps or as self moving concrete pumps mounted on a crawler.

Difficulties have been expe-rienced with pumping mixes that h a v e too large a pro p o r tion of coarse aggre g a t e. This is tried-and-true performance you can count on. LEGENDARY MP ENGINES Power and speed controls are tuned for consistent speed and torque across the wide operating range required for smooth concrete pumping.

Obstacles during the concrete casting path can be easily overcome by such pumps. For all sewage pump stations the pumps must comply with NEC Class 1 Division 1 Group C D hazardous locations. Putzmeister M 42-5 truck-mounted concrete pump in Bonn Nowadays the pumping of freshly-mixed concrete is a link in the process chain that one can scarcely imagine living without.

SANY trailer mounted concrete pumps have participated in 80 of the high-rise buildings with a height above 300 meters completed or under construction. 33CX The oil flows in closed circuit from the rexroth pump to hydraulic cylinders and return to the pump. EN 12001 deals specifically with concrete pumps and is available from the National Standards.

In this category there are dwg files useful for the design. The Concrete Mix Design Manual for Nigeria like any document of this nature must be subjected to periodic review. Optimal boom design for every application.

Delivery and drive cylinders operate in perfect harmony with one another to. A three-phase research study was carried out to 1 investigate performance of pumped concrete in field conditions 2 identify concrete properties affecting pumpability and 3 assess the effects of pumping on concrete air void system. THE TRUCK MOUNTED PUMP Concrete boom pumps are complex dynamic systems with a variable number of segments linked together by kinematic joints and moved by hydraulic actuators.

EVERDIGM pumps utilize FFH System which is widely recognized and proven in the industry. The boom tip housing the device for placing the concrete may be very far from the pump or in very high place Figure 1. As s h o wn in Table 2 the quantity of coarse aggregate must be re d u c e d as the maximum size becomes s m a l l e r.

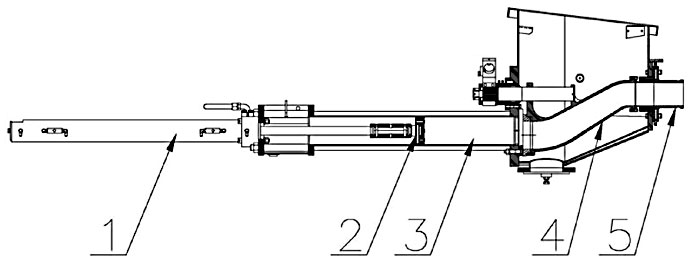

Design of Automobile Concrete Pump DOI. This is descri b e d later in the section on mix design. Unlike the more commonly used standard box design which places a welding seam precisely at the edge of maximum stress the H-Box features horizontal plates that run perpendicular to the vertical plates below this critical area.

Line concrete pumps are compact units that are mainly used for small construction projects. Mack has led the industry in integrated design and manufacturing for over 100 years. This guide discusses concrete placement using the pumping method and how it affects the supplied concrete mixture when considering pumpability in mixture design and with the goal to obtain optimum concrete pumping results.

1 AMERICAN CONCRETE PUMPING ASSOCIATION National Office Headquarters. The detailed design of the concrete pump is subject to the Machinery Directive 200642EC and associated Irish legislation the European Communities Machinery Regulations 2008 SINo407 of 2008. Concrete pumps concrete mixers construction machines.

Mix Design and Pumped Concrete A simple method of concrete mix design for pumpable concrete based on an estimated weight of the concrete per unit volume is described in the paper. And shows how this automobile concrete pump works Figure 5. Combined circuit for both systems Mechanical and Hydraulic.

Model 510 Concrete Pump. 12Scope This guide for concrete pumping discusses equipment use proper mixtures for good pumpability and field prac. Supervisors maintenance staff operators crew order takers and other staff involved in any aspect of concrete pumping shall receive adequate and appropriate training on the minimum standards contained within this handbook.

In addition the Irish Standard IS. Four-inch 4 slump is very common with normal weight concrete and is a good average slump for pumping. INDUSTRY-LEADING DRIVELINE AND POWER DIVIDER.

5224 West State Road 46 PMB 405. Concrete pumping records across the globe. Ciently used in a concrete mix.

606 Enterprise Drive Lewis Center OH 43035 Phone. Putzmeisters exclusive H-Box design is best adapted to handle the day-to-day stresses of concrete pumping. The ingenious geometry of Putzmeister concrete pumps was designed for all standard concretes.

The tables and figures presented are worked out by the author from a wide range of Indian materials. Liebherr truck mounted concrete pumps featuring various configurations with boom sizes of up to 50 metres radius are perfectly designed for cost-effective supply of concrete onto the building site. With the current state of concrete technology pumpable con-crete is no longer classed as a special concrete instead it is a construction material regulat-.

Every reference document goes obsolete if left to drift for eternity that is without review. The method is suitable for normal weight concrete with admixture. Slump is a measure of concrete consistency or fluidity.

To achieve this each of the planned 54 floors are rotated by 3 to the one be-low and the resulting effect is. Locate with template Secured in pedestal or embedded into floor slab 1212017 PUMP INSTALLATION PRESENTATION 39. ASTM A48 Class 40B Cast Iron.

What is most striking is the spiral design of the building.

43 Meter 5 Section Rz Boom Concrete Pump Alliance Concrete Pumps

How Does A Reed Concrete Pump Work

Fatigue Life Prediction For Boom Structure Of Concrete Pump Truck Sciencedirect

Truck Mixers Cifa S P A Pdf Catalogs Documentation Brochures

How Does A Reed Concrete Pump Work

Pdf Centrifugal Pump Design Materials And Specifications

All Putzmeister Catalogs And Technical Brochures

Fatigue Life Prediction For Boom Structure Of Concrete Pump Truck Sciencedirect

0 comments

Post a Comment